The 5 Most Common Construction Project Delivery Methods

This post has a straightforward, some would say boring, purpose: To provide a comprehensive summary of the traits, benefits and limitations of the most common project delivery methods a business owner or developer will likely consider for their project. It’s not sexy, but creates a foundation for topics we will discuss in future posts.

It is not an overstatement to say that the wrong team structure will make your entire design and construction process more difficult, stressful, costly and time consuming – and much less likely to achieve your objectives.

Because this topic is so critical, we will eventually be posting several articles related to the relative strengths and weaknesses of these project team structures. The first of these is our “Questions to Ask When Selecting the Project Delivery Model” article already posted to JJH3group.com. Please check in periodically for future posts, and don’t hesitate to reach out with specific questions and/or topic requests.

THE FIVE PROJECT DELIVERY METHODS WE’LL DISCUSS

DESIGN-BID-BUILD

DESIGN-BUILD

CONSTR. MANAGER-AT-RISK

MULTIPLE PRIME / CM-AS-ADVISOR

INTEGRATED PROJECT DELIVERY

DESIGN-BID-BUILD (D-B-B) PROJECT DELIVERY METHOD

DESIGN-BID-BUILD CHARACTERISTICS:

The most commonly used delivery method for construction projects in the U.S.

Design, procurement and construction stages typically done in sequence.

Owner hires independent designers and consultants to create a 100% complete set of documents for bid.

Contractors bid project exactly as designed; typically selected on fixed-price, low bid.

Best suited for less complex projects.

Best for Owners without an aggressive schedule and for whom low price is a priority.

DESIGN-BID-BUILD ADVANTAGES:

Owner retains control of design and construction via separate contracts with Architect and GC.

Design 100% complete prior to start of construction, so changes during design are easily accommodated.

Relatively easy to implement – procedures and legal issues are well-defined and contract scope is clear.

Independent, adversarial relationship between Designer and Contractor provides oversight for the Owner.

Maximum number of bidders; typically awarded to lowest bidder.

Project cost is fixed at contract award

DESIGN-BID-BUILD CONSIDERATIONS / DISADVANTAGES:

Most litigious delivery form –team members may work less collaboratively to protect their self interests.

Owner must allocate the time and resources to manage the process and resolve conflicts between the Designer and GC.

Owner bears all risk associated with the completeness and accuracy of the design documents. Contractors only bid what is explicitly outlined in the CDs; errors or omissions may result in change orders or redesign.

The designers’ limited experience with construction costs, material availability and constructability issues potentially results in higher bids and/or future change orders.

Value engineering is limited without Contractor involvement during the design process.

Project cost is unknown until bids received. If the bids do not meet the budget, redesign may be required.

Fixed-price, low-bid contract can result in cheapest suppliers and subcontractors doing low-quality work.

Design and construction are sequential, typically resulting in longer schedules than other delivery methods.

DESIGN-BUILD (D-B) PROJECT DELIVERY METHOD

DESIGN-BUILD CHARACTERISTICS:

A collaborative delivery method that combines the design and construction providers under a single contract. While the team can be led by the Designer, it is more common for the General Contractor to be the contracted party.

Requires timely decisions throughout the process.

Proven to work on both simple and complex projects; the aggressiveness and dependability of design-bid proposals are heavily dependent upon the Owner’s ability define the scope.

Owner issues a Design-Build RFP outlining the basic project parameters and performance expectations.

Bidders propose a complete design and construction package, typically qualification-based with a target budget and defined general conditions.

Given the more loosely-defined, more qualifications-based proposal scope, design-build contracts are typically negotiated rather than hard bid. The contract will typically have an open-book, Guaranteed Maximum Price (GMP) component and a mutually beneficial incentive structure that aligns the Design-Builder’s interests with those of the Owner.

Having the GC involved during the design process allows for value engineering and fast-tracking.

An independent CM is often hired as Owner’s Representative to provide oversight over the Design-Builder.

DESIGN-BUILD ADVANTAGES:

Provides a single point of contact for the Owner; assigns much of the Owner’s risk to the Design-Builder.

Owner retains some control of design, but is removed from conflicts between the Designer and Contractor and is not responsible for design errors and omissions.

The Contractor can shorten the schedule by beginning construction before design is completely finished.

Value engineering and construction best practices can be integrated in real time, allowing the design to better align with the Owner’s budget, schedule and quality goals.

Requires less Owner expertise and resource dedication – allowing Owner to focus on their own business.

Emphasis on best value with improved project quality.

The early, firm GMP provides Owner budget control/certainty and opens up alternative financing options.

Shortened project schedule reduces general conditions cost and material/labor price escalation.

DESIGN-BUILD CONSIDERATIONS / DISADVANTAGES:

Owners give up some control over design and must be willing to let Design-Builder make many decisions.

A poorly-defined performance specification by the Owner creates risk for higher costs and lower quality.

Fewer qualified firms, and many Owners are unqualified to adequately define the scope, vet proposals and negotiate D-B contracts. RFP process opens up inexperienced Owners to untrustworthy design-builders.

Owners are sometimes hesitant to delegate so many responsibilities to a single entity and concerned about potentially conflicting interests when one firm oversees both the Designer and Contractor.

Similarly, some Owners worry that the Design-Builder will be disinclined to provide market rate fees and limit general conditions costs, and that they may favor unqualified subcontractors and suppliers.

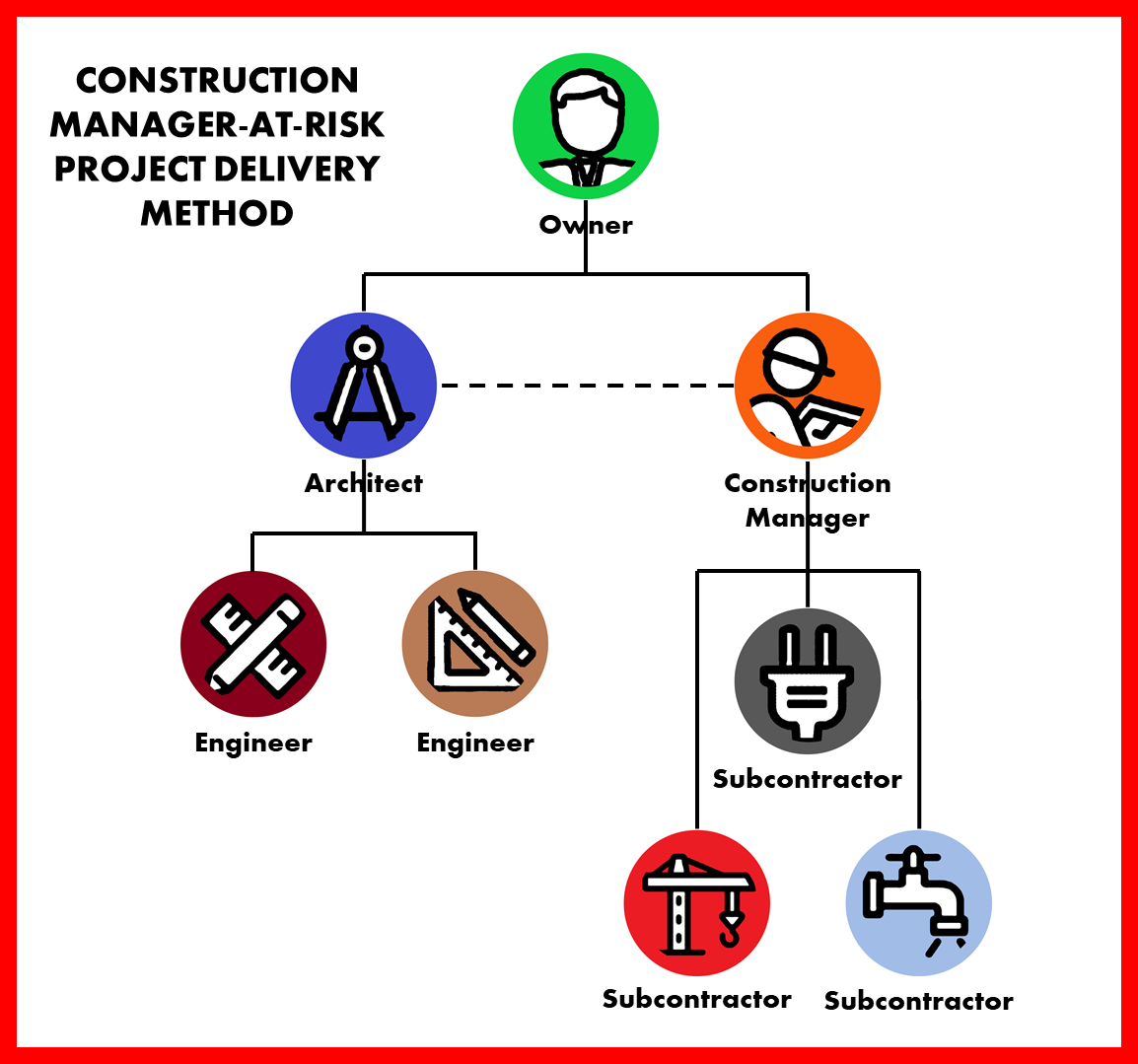

CONSTRUCTION MGR-AT-RISK (CMc) DELIVERY METHOD

CONSTRUCTION MGR-AT-RISK CHARACTERISTICS:

A derivative of Design-Bid-Build, but with a CM hired by Owner to oversee the entire process.

Often referred to as “CM-As-Constructor” (CMc).

Good option for Owner willing to pay for design innovation and a defined schedule and price.

Most often used on larger, complex projects.

As in D-B-B, Owner contracts with two parties – the Designer and the CM –both selected on qualifications and fees. The CM then manages all agreements with subs and charges a management fee for that service.

The CM serves as a consultant to the Owner in the development and design phases, catching gaps in the design scope and finds value engineering options.

During the design phase, the CM establishes a Guaranteed Maximum Price (GMP) – providing early cost certainty. The CM accepts GMP risk in exchange for the opportunity to share savings under the GMP.

Typically open-book. CM will take subcontractor bids and select the bid they believe best meets the Owner’s quality, cost and performance needs without exceeding the GMP. Once construction begins, the CM serves as the General Contractor – holding all subcontracts, scheduling the work, overseeing the performance and negotiating change orders.

CONSTRUCTION MANAGER-AT-RISK ADVANTAGES:

Owner retains control of design, but project requires less Owner involvement as CM administers the contracting and construction.

Collaborative effort from project inception creates a higher quality project. CM provides early estimating, scheduling, constructability, logistics, value engineering and life-cycle cost input.

Can lock in on a final GMP earlier in the process, subsequent options can be clearly quantified and priced.

Construction can overlap design, fast-tracking project delivery and reducing overall project duration. CM can procure long lead items during design to compress the schedule.

CONSTRUCTION MANAGER-AT-RISK CONSIDERATIONS / DISADVANTAGES:

Generally has a slightly higher cost to the Owner because of the Construction Manager’s fee.

An Architect independently contracted to the Owner may bristle at input from CM during design.

Owner is liable to CM for design errors and omissions that lead to schedule delays and increased costs.

Reduced Owner control of construction; Owner can become less hands-on throughout the process.

MULTIPLE-PRIME SUBCONTRACT / CM-AS-ADVISOR (CMa)

MULTIPLE PRIME / CMa CHARACTERISTICS:

Often the mandated model for public projects that require maximum control and oversight of contractors at all levels.

Owner enters into separate contracts with firms leading each of the major portions of the project:

One contract , typically with the Architect, would include engineering, consultants and interiors.

A second contract would often be with a General Contractor or Carpentry/Concrete Subcontractor, depending upon the nature of the Project, that would cover several categories of subcontractors.

The Owner would then typically have individual contracts with each of the major “Prime” trade subcontractors: Electrical, Mechanical, etc.

A Construction Manager is often contracted on such a project to provide design and construction oversight similar to the role performed in CMa.

The CM and Designer prepare bid documents from which specialty subcontractors offer their lowest price.

Design, procurement and construction phases are typically done in sequence.

MULTIPLE PRIME / CM-AS-ADVISOR ADVANTAGES:

Owners gain greater contractual control over the design and construction of the project.

Contractors and/or CMc can be involved early and participate in the value engineering process.

Combines the fast-track capability of D-B and CMc if Prime Subcontractor packages are bid early enough.

MULT. PRIME / CMa CONSIDERATIONS / DISADVANTAGES:

Owner essentially takes on the role of General Contractor, including the time, resources and risk that entails.

Owner is responsible for design changes, errors and omissions.

Risk of poor coordination and communication with so many independent subcontractors; managing schedules can be difficult.

Reliance on several prime contractors makes it difficult to determine the final cost until late in the process.

Increased potential for change orders due to multiple prime contracts and Owner’s responsibility for communication, coordination and scheduling.

The CM is not at-risk and has no contractual relationship with – or authority over – subcontractors. Owner is exposed to additional risk in that they are accountable for the performance of all of the subcontractors.

Potentially complex management of warranty services.

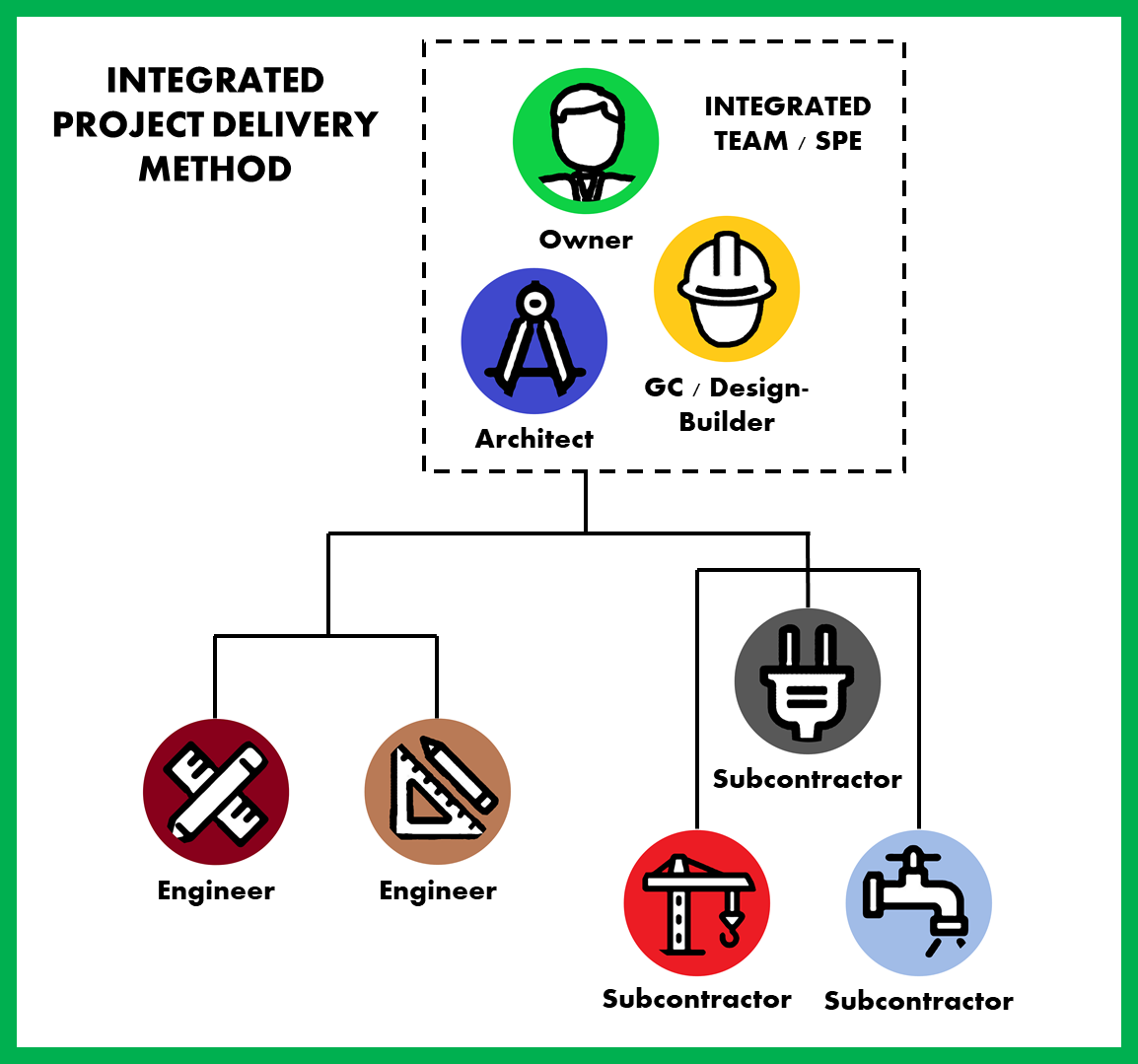

INTEGRATED PROJECT DELIVERY (I.P.D.) METHOD

INTEGRATED PROJECT DELIVERY CHARACTERISTICS:

An up-and-coming, highly collaborative delivery method in which the Owner, Architect and GC/DB/CM enter into a single joint contract – often through creating of a Single Purpose Entity (SPE) LLC.

The primary goal of the integrated method is to spread responsibility and risks, and align goals and benefits, among the major stakeholders.

The primary team members are hired based on qualifications and the project budget is collaboratively set, typically without a GMP.

Collaborative approach intended to incorporate construction expertise, pricing support and value engineering into the design process.

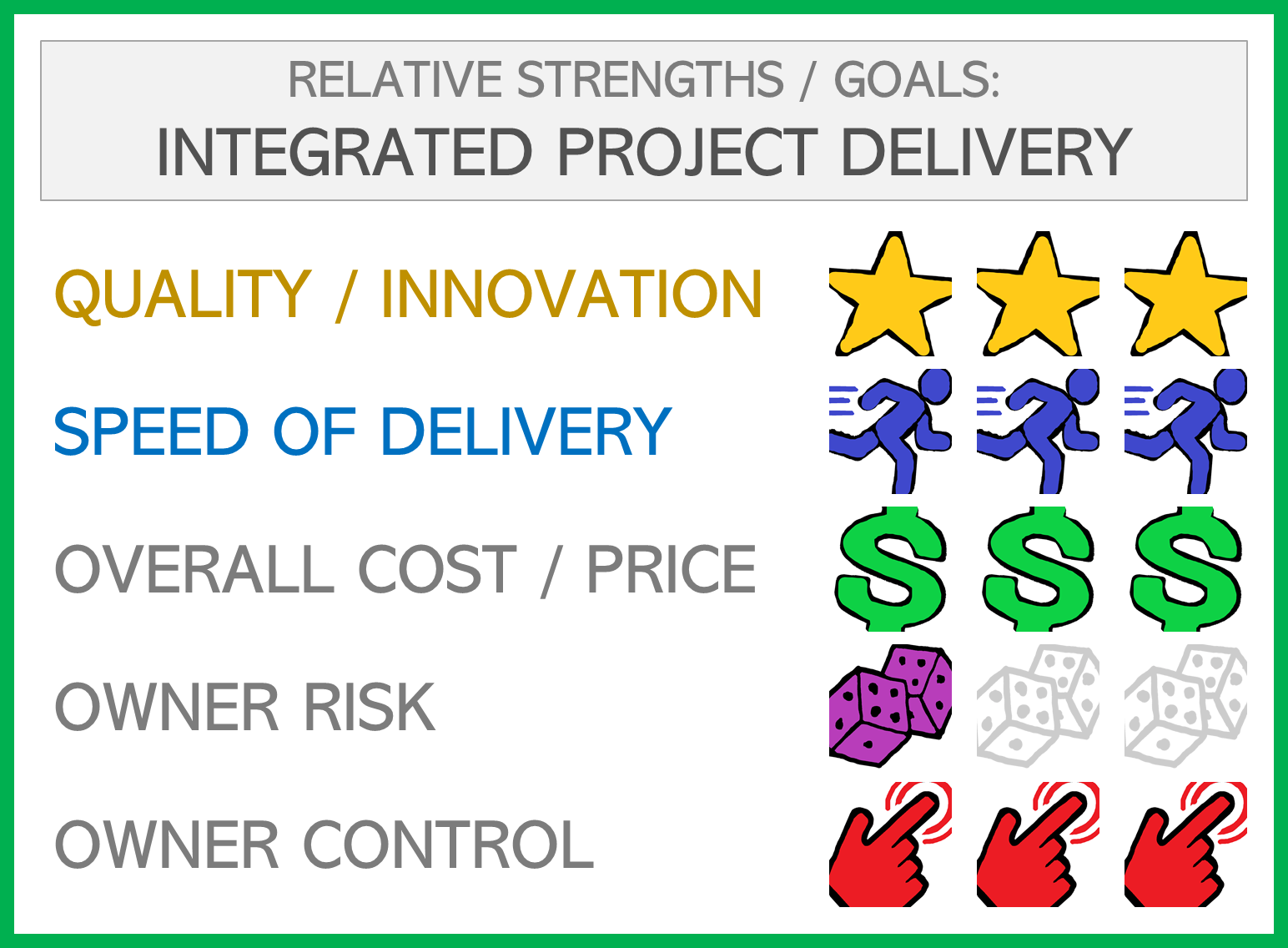

INTEGRATED PROJECT DELIVERY ADVANTAGES:

Shared risks and rewards between Owner, Designers, GC/DB/CM and major trade partners creates a culture of collaboration from the beginning.

Team members share a commitment to mutually-agreed-upon budgets and schedules.

Creates a more transparent, innovative process with an emphasis on value, performance and quality.

Design and construction experts contribute to all project phases, with all members of the team encouraged and willing to innovate in pursuit of shared goals and objectives.

Facilitates fast-track construction.

INTEGRATED PROJECT DELIVERY CONSIDERATIONS / DISADVANTAGES:

Owners who choose this method must be comfortable making gut-level decisions about whether the various team members are right for the project and will work well together.

Requires heavy Owner involvement throughout the entire design and construction process.

Requires a comprehensive and carefully prepared contract. The complicated contractual agreements can sometimes be expensive side to negotiate and implement.

Compensation to individual team members doesn’t necessarily equate to contribution effort.

Requires team members that are flexible, continuously engaged, knowledgeable and capable of performing in a manner that supports the greater good of the project.

Coordination of documentation and information among the integrated team requires additional time and effort from all of the key parties.

Interested in learning more? JJH3group is a commercial real estate development and design-build advisory firm based in Milwaukee, WI. The firm was founded on a core set of guiding values and principles, providing clients with quality development, design and construction services across a broad spectrum of project types. We are experienced in assembling multidisciplinary teams and partnering with public and private stakeholders to deliver well-designed, functional and efficient facilities. Let JJH3group help you plan and manage your next project. For a free consultation, please contact us at JJH3group@gmail.com or (414) 333-3430.